DETROIT – Ford Motor and battery supplier SK Innovation plan to invest more than $11.4 billion in new U.S. facilities that will create nearly 11,000 jobs to produce electric vehicles and batteries.

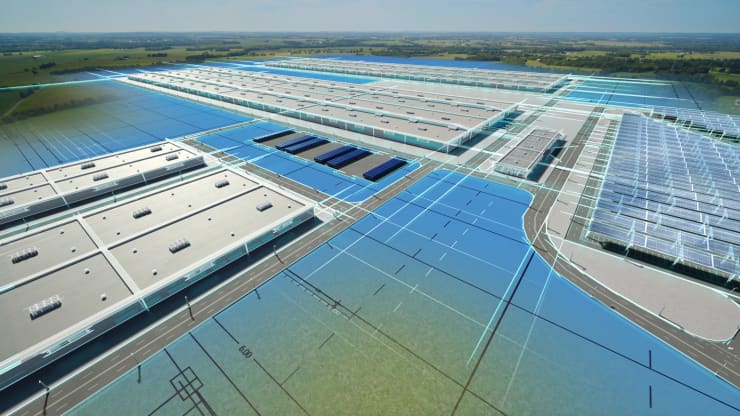

Ford is building twin lithium-ion battery plants in central Kentucky through a joint venture with South Korea-based SK called BlueOvalSK as well as a massive 3,600-acre campus in west Tennessee, the automaker said Monday night. The campus will include another a battery plant built with SK along with a supplier park, recycling center and a new assembly plant for electric F-Series trucks, Ford CEO Jim Farley told CNBC.

The plans are the latest of Ford’s to increase development and production of electric vehicles — including batteries — under Farley, who began leading the automaker a year ago this week. They also bolster President Joe Biden’s call for companies to onshore supply chains amid a global shortage of semiconductor chips that has disrupted several industries, including automotive.

The investment is part of Farley’s “Ford+” turnaround plan to make the automaker’s traditional operations more profitable and better position it for emerging sectors such as autonomous, electric and connected vehicles.

“This is the new Ford,” Farley told CNBC during a phone interview. “It’s time. We are putting shovels in the ground, 11,000 new workers. … It’s an enormous commitment to build these digital products.”

Ford does not expect to take on any additional debt to fund the plans, according to Farley. He said moves will be funded through the company’s profits.

The new investment comes on top of the $30 billion the company previously said would go to electric vehicles through 2025, about $7 billion of which had already been invested before February.

Production at the plants, aside from one of the battery plants in Kentucky, is expected to begin in 2025, the company said. The second battery plant in Kentucky is expected to come online in 2026, according to Ford.

‘Pivotal moment’

The “new Ford” is a drastic pivot from Farley’s predecessor, Jim Hackett, who previously said the automaker saw “no advantage” in producing its own battery cells. It comes as Ford’s crosstown rival General Motors spends $4.6 billion through a joint venture with LG Chem for battery production, starting in 2023.

Farley said the investment should be further proof that Ford, which many on Wall Street believed was behind on EVs, is positioned to be a leader in the segment. “I don’t know of any other company making this announcement. Why would you ever think we’re behind? We’re ahead,” Farley said.

Shares of Ford have more than doubled since Farley became CEO of the automaker almost a year ago.

About $5.6 billion of Ford’s investment with SK will go to a new campus called Blue Oval City in Stanton, Tennessee and $5.8 billion for the two factories in Glendale, Kentucky. Ford will cover about $7 billion of the $11.4 billion, according to Lisa Drake, Ford’s North America chief operating officer.

“This is a really pivotal moment for us and our country today,” Drake told reporters during a call. “We are announcing the largest single investment in new manufacturing facilities in the 118-year history of Ford.”

The three new plants for BlueOvalSK will enable 129 gigawatt hours a year of U.S. production capacity for Ford — enough to power 1 million electric vehicles annually, Ford icials said. That’s more than half of the EV production capacity Ford expected to have globally by 2030.

“This is truly a staggering project, and one that speaks to Ford’s ambition to the fast-growing U.S. EV industry,” SK Innovation global head of marketing Yoosuk Kim said during a call.

New F-Series coming

Ford expects the new vehicle manufacturing facility in Tennessee to be carbon neutral once fully operational, including zero-waste-to-landfill processes.

Farley said the plant will build new electric F-Series pickups. He added the next-generation pickups will be solely designed to be EVs, unlike the upcoming F-150 Lightning that is based off the traditional pickup with an internal combustion engine.

“We’re going to build an all-electric bottom up, optimized product platform in this plant. It will be the largest plant in the history of our company,” Farley said. “We’re going to build lots of fantastic F-Series electric vehicles there. We’re not going to be specific about what type.”

Farley said the company is “reinventing what a pickup truck would be,” including the range, with this announcement. Drake said Ford expects one-third of full-size pickups sold in the U.S. to be fully electric by 2030.

Ford’s current F-Series lineup includes the F-150 and larger versions of the full-size truck as well as medium-duty trucks and chassis cabs meant for commercial buyers.

Farley and Drake compared the significance of the new EV plants to company founder Henry Ford’s mass production of the Model T, which made vehicles more affordable and accessible to the general public.

Ford previously said it expected at least 40% of its sales globally to be electric vehicles by the end of this decade. The target was announced prior to the Biden administration setting a target last month for half of all new auto sales to be electric vehicles, including plug-in hybrid models, by 2030

In addition to the manufacturing facilities, Ford said it plan to invest $525 million over the next five years, including $90 million in a pilot program in Texas, for training skilled technicians to service EVs.

“This is just the beginning of our aspirations to lead America in the next century of sustainable transportation economy,” Drake said. “This investment is catapulting us ahead to lead the electric revolution.”