Southwest Research Institute worked with government and commercial collaborators to successfully develop and demonstrate full-scale turbomachinery for one of the world’s first supercritical carbon dioxide (sCO2) power systems for a concentrated solar power (CSP) plant. The technology combines sCO2 power cycles with integrated thermal energy storage.

The project was supported by the U.S. Department of Energy’s APOLLO program, which was created to improve performance and reduced the cost of electricity from CSP plants. The 10MW sCO2 turbomachinery has successfully completed performance and endurance tests in a closed-loop environment.

sCO2 is carbon dioxide held above a critical temperature and pressure, which causes it to act like a gas while having the density of a liquid. It’s also nontoxic and nonflammable, having been used in dry cleaning processes, low-GHG refrigeration systems, as well as to decaffeinate coffee.

The fluid properties in its supercritical state makes sCO2 a highly efficient fluid to generate power due to high density, low viscosity and favorable heat transfer properties.

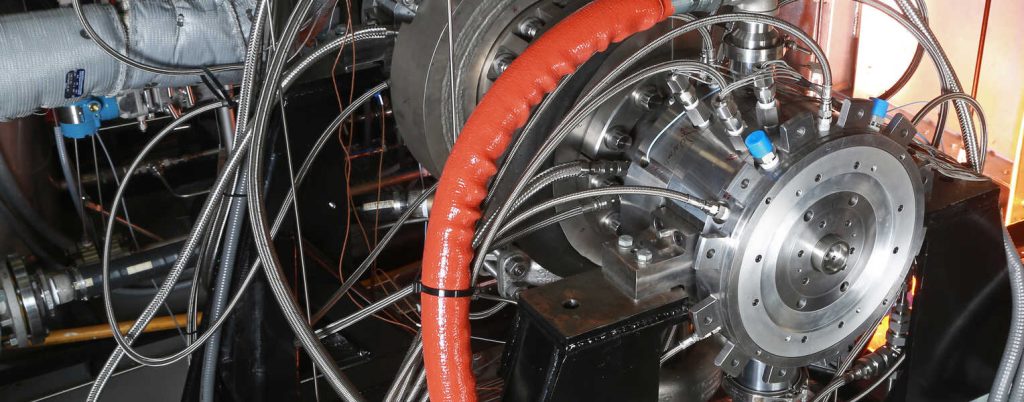

“Advancing grid-scale energy storage is an important step to enabling full penetration of renewables into power generation. Utilizing sCO2 as a working fluid can increase the efficiency of a CSP plant by as much as 10 percentage points,” said Dr. Jason Wilkes, manager of SwRI’s Rotating Machine Dynamics Section. “The high efficiency of the sCO2 cycle also allows the turbomachinery to have a smaller footprint—it is 1/20th the size of a standard steam turbine, allowing for improved installation in most environments.”

CSP technology uses mirrors or lenses to concentrate a large amount of sunlight onto a receiver, which typically converts concentrated light into heat and extracts thermal energy to generate power using steam turbines. The system stores the energy as heat, which can then be converted to on-demand energy using sCO2 power cycles, improving efficiency and reducing operating costs.

“sCO2 power cycle technology is a fraction of the size of conventional turbomachinery, offering improved performance for numerous applications. The successful MW-scale demonstration of sCO2 technology at full-cycle conditions is an exciting milestone,” said Dr. Tim Allison, director of SwRI’s Machinery Department.

SwRI and Hanwha Power Systems, a global energy equipment company with headquarters in South Korea, developed and demonstrated the new integrally geared sCO2 turbomachinery tested at full-scale compressor conditions and full-pressure full-temperature testing of the turbine at unprecedented MW-scale conditions of up to 720 °C and 275 bar. The system is planned to be integrated into a CSP pilot plant at a future date.