The journey of lithium batteries is relatively young, born from innovators’ combined efforts in the USA, UK, and Japan. The fruits of their labor were acknowledged in 2019 when Stanley Whittingham, John Goodenough, and Akira Yoshino received the Nobel Prize, representing their respective countries.

Before delving into the realm of battery variety, let us take a moment to understand the inner workings of these powerhouses. A battery consists of an anode, the negative electrode, and a cathode, the positive electrode. Nestled between them resides the electrolyte, usually in a liquid form. During the charging process, positively charged ions flow from the cathode through the electrolyte to the anode, where they are stored until the battery reaches its full charge.

Simultaneously, negative electrons journey through the charging circuit from the negative electrode to the positive one. When it’s time to discharge, the electrons reverse their path, flowing through the device in need of power, such as an electric motor. Eventually, all the ions retreat through the electrolyte back to the cathode, signifying a fully depleted battery.

In the realm of lead acid batteries, the cathode boasts a composition of lead dioxide, while the anode is fashioned from metallic lead. Sulphuric acid serves as the electrolyte in this case. On the other hand, lithium-ion batteries commonly adopt graphite as the anode and employ lithium salt as the electrolyte. However, the diversity emerges in the various cathode compositions.

The prevailing contenders are LFP (lithium iron phosphate) and NMC (nickel manganese cobalt), although numerous others vie for recognition as ongoing advancements aim to enhance performance. The anode largely dictates charging times among the two electrodes, whereas the cathode primarily influences the battery’s range and cost. Consequently, cathodes have been the focal point of development, hence the prevalence of LFP and NMC batteries in the current market. LFP, being an abbreviation for lithium iron phosphate, offers an economical alternative due to the abundance and stability of lithium supply, even amid rising material costs. Hence, it finds its place in more affordable electric vehicles like those produced by MG, Hyundai, and certain Tesla base models.

NMC, an acronym encompassing nickel, manganese, and cobalt, represents the elements comprising the cathode in this battery variant. Notably, cobalt holds a strategic status as half of the world’s reserves reside in the Democratic Republic of the Congo, where dubious safety and human rights standards plague artisanal mining operations responsible for extracting 20% of the precious resource. China plays a significant role in the ore processing, accounting for nearly half of the global production.

The realm of cathodes introduces a significant disparity between NMC and LFP, with NMC boasting superior performance at a hefty cost, constituting 62% of the cell’s expenses. To optimize its capabilities, the composition of NMC varies. An NMC 532 cell, for instance, contains 50% nickel, 30% manganese, and 20% cobalt. However, the current trend gravitates toward NMC 811, showcasing 80% nickel while reducing manganese and cobalt to a mere 10%. On the other hand, pioneers like Volkswagen delve into high-manganese chemistries, which offer comparable performance to NMC 532 at the expense of LFP’s cost-efficiency.

While cathodes take center stage in development, anodes are still intact, with promising experimentation involving the incorporation of silicon into graphite materials. Furthermore, the exploration extends to alternative chemistries like sodium-ion, as sodium’s abundance begins to rival the efficiency of LFP cells.

Enough with the chemistry, let’s examine the components constituting a battery. At its core lies the cell, typically cylindrical and resembling a slightly enlarged version of the familiar AA battery. However, some manufacturers opt for pouch cells, comparing little envelopes, which exhibit the highest power and energy densities at the cellular level. The final type, prismatic cells, take the form of rectangular blocks, although their presence in automotive applications is rare.

Regardless of their geometry, these cells are interconnected in modules, which, in turn, are joined together to form a complete battery. For instance, the Tesla Model S comprises 16 modules, each housing 444 cells. The modules are linked in series, resulting in a battery encompassing 7,104 cells and boasting a capacity of nearly 90 kilowatt-hours (KWh). Different configurations of series and parallel connections in various batteries dictate voltage and capacity.

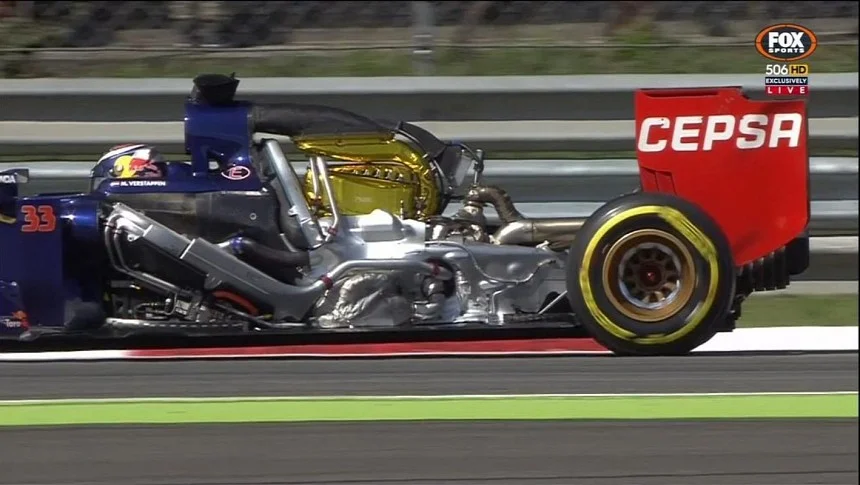

The remaining components of a battery hold tremendous significance. Firstly, the cooling system assumes a crucial role maintaining optimal temperature conditions for the battery’s operation. While road cars typically rely on a water and glycol mixture, high-performance batteries may adopt immersion in dielectric oil to reduce weight. An overheating battery suffers from inefficiency and risks thermal runaway, leading to potential fires.

Lastly, we encounter the battery management system (BMS), an intricate blend of electronics and software. This sophisticated system collects data from each cell, ensuring voltage, charge, and temperature balance among them. Moreover, it monitors safety-critical aspects. The software then relays information regarding the state of charge and health to the energy distribution system, which determines the electrical conduction pathway within the battery.

In essence, while the lithium-ion battery powering your flashlight shares similarities with its counterpart in an F1 car, it represents a simplified example of an extraordinarily intricate energy storage device that can be developed.