Humans have yet to even step foot on Mars, but architects are already designing homes people can live in on the distant planet for NASA.

AI SpaceFactory, a “multi-planetary architectural and technology design agency” in New York City, designed a habitat called “Marsha,” which can be 3D-printed using materials available on the Red Planet. The design won NASA’s 3D-Printed Habitat Challenge this month.

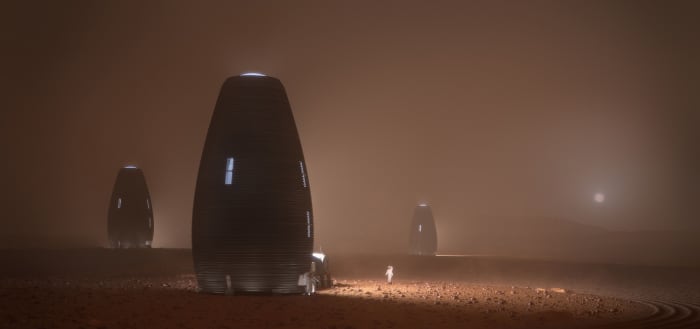

Take a look inside the Mars habitat, via renderings from AI SpaceFactory.

The cone-like pods are 15 feet high and 8 feet in diameter, and they would sit vertically on Mars’ dusty, rocky surface. The pods are designed to be 3D-printed in just 30 hours without any human assistance.

Inside, the habitats have four levels inside, connected by spiral staircases.

A ground-floor level would include a sealed hatch for entering and exiting the pod in space suits, as well as laboratories for astronauts to conduct tests and other work. Other levels would include a kitchen, a garden for growing plant-life, a level for exercising and other recreational activities, and four “sleepy pods” — private living quarters with a bed and desk.

The interior of the pods, AI SpaceFactory says, needed to be “light, airy” and comfortable for humans living on a faraway planet with very different living conditions than Earth, including extreme temperature swings that can vary between 70 degrees Fahrenheit and minus-100 degrees in the same day. The agency describes its pods as offering a “tiny bubble of Earth on a distant world.”

“Each level has at least 1 window, which, together, cover the full 360 degree panorama. Indirect natural light from the large water-filled skylight and intermittent windows floods the interior while still keeping the crew safe from harmful solar and cosmic radiation,” according to AI SpaceFactory.

The pods would be manufactured using “an innovative mixture of basalt fiber extracted from Martian rock and renewable bioplastic (polylactic acid, or PLA) processed from plants grown on Mars,” AI SpaceFactory says on the agency’s website, eliminating the problematic issue of interplanetary transport of materials.

Humans may still be several years away from even transporting people to Mars (SpaceX’s Elon Musk has claimed he can make it happen by 2024, though NASA is shooting for the 2030s). But NASA launched its design competition in 2015, asking architects and technology experts to design habitats suitable for humans to live in on Mars. The designs had to be able to be 3D-printed using sustainable materials found on Mars, as NASA wants to use Mars rovers outfitted with large-scale 3D printers to build habitats before humans even arrive.

AI SpaceFactory was awarded $500,000 for its winning prototype, which beat out 60 different teams (a team from Penn State University finished in second place, winning $200,000). AI SpaceFactory’s biopolymer composite of basalt fiber and bioplastic “was found to be stronger and more durable” than prototypes using concrete from other competing teams, NASA said.

Of course, NASA scientists aren’t the only people thinking about supporting human life on Mars. SpaceX CEO Elon Musk regularly talks about his vision for Martian colonies, and he even tweeted earlier this year that SpaceX could have a fully “self-sustaining city” on Mars by 2050. Musk even told Popular Mechanics that Mars colonies could build glass domes with plant-filled parks inside to create “an outdoorsy, fun atmosphere.”