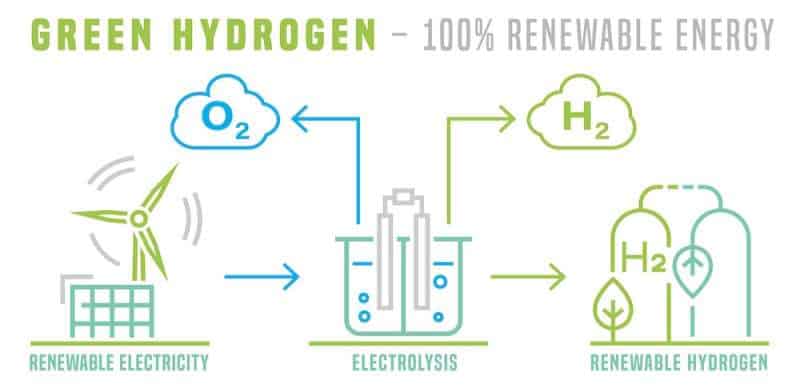

Australia is well-positioned to be a global leader in green hydrogen production. Green hydrogen is produced using a renewable power source such as solar or wind. As a substitute for fossil fuels, it will help to meet growing renewable energy needs.

However, high-quality water is needed to produce hydrogen. Supplies of high-quality water must also be secured into the future to support our agriculture, industries, cities, towns and communities. Climate change and population growth will increase pressure on these supplies.

Community discussion is needed to identify where the water to produce hydrogen will come from. We need to ensure this developing industry does not disadvantage other water users, as we discuss in our new white paper.

Green hydrogen industry looks set to boom

Green hydrogen is likely to partially replace petrol and diesel for large vehicles such as trucks and heavy machinery as Australia moves to a carbon-neutral economy. It has the advantage of being a fuel suitable for sectors such as mining and transport that are struggling to reduce emissions.

The green hydrogen market is expected to grow rapidly. Hydrogen energy outputs in Australia are estimated to exceed 100MW by 2025. More than 90 projects representing A$250 billion in investment are planned.

Most demand for hydrogen this decade is likely to be domestic—for chemical production, industrial processes and other uses. In the longer term, major export demand is expected from the Asia-Pacific.

By 2040, Australia’s green hydrogen production cost is predicted to be the equal-lowest in the world. Electrolysis, which splits water molecules into hydrogen and oxygen, will be the main method of producing this green hydrogen.

How much water are we talking about?

The amount of water needed to generate green hydrogen varies. The exact amount of water required depends on the technology used to produce hydrogen, the water quality and any need for cooling or water purification.

On average, a liter of water can produce enough hydrogen to deliver about 10 megajoules of energy. That’s enough to push a 50-ton truck 15 meters.

The previous Australian government predicted the hydrogen industry could be worth A$50 billion a year by 2050. At that scale, it would need about 225 billion liters (gigalitres) of water. While that’s roughly as much as residents of a city like Perth use in a year, it’s only about 3% of the water used for agriculture in Australia in 2020-21.

There are many possible sources of water. Surface water, groundwater and recycled water are all available inland. Coastal areas have unlimited seawater, which can be desalinated for hydrogen production.

But there are trade-offs whenever we allocate a water resource. In many areas, the available fresh water is fully allocated to towns, cities, agriculture, industry and the environment. The pressure on water supplies will increase as populations grow and much of Australia becomes hotter and drier under climate change.

Further, most water would have to be treated to be suitable for hydrogen production. Treatment can be expensive and uses additional energy, as does desalination and pumping water long distances.

Failure to plan for water use could be costly

Current issues in the gas industry provide a cautionary tale. High gas prices in eastern Australia can be deemed the result of failure to consider impacts on domestic customers of developing a gas export industry.

Western Australia, in contrast, reserved enough gas for domestic users. As a result, its prices are among the lowest in the OECD.

A similar failure may arise if corporations buy high-quality water for hydrogen generation, diminishing supplies for agricultural, domestic or environmental use. North Africa exports substantial amounts of green hydrogen to Europe, but this is controversial because of regional water shortages.

In Australia, competition for water will intensify due to climate change and ongoing demands from agriculture—72% of national water consumption in 2020-21—industry, mining, households and the environment. Using potable water to produce hydrogen may be at odds with community expectations.

Care must be taken to ensure industry expansion does not adversely affect other users. This will be particularly difficult in Australia because rainfall is highly variable by world standards—not news to those who have lived through recent years of drought then flooding rains.

So what are the likely solutions?

The key challenge is to produce hydrogen in large quantities in a way that is cost-effective and sustainable.

This can be achieved by planning effectively for industry growth. Our white paper identifies public policy and industry-related issues posed by this growth.

We must identify regions likely to support hydrogen production and storage, find nearby sources of water and calculate volumes needed. Then, we must develop plans to support existing water users while providing a viable solution for the green hydrogen industry.

Alternative sources such as recycled water or treated groundwater are likely part of that solution. Harvesting water from industrial and urban wastewater could be a game changer. It would require moderate treatment but have fewer effects on other water users.

We will learn a lot from pilot programs such as the New Energies Service Station in Geelong, which will create hydrogen from 100% recycled water.

In planning to overcome the challenges, we’ll need to develop relevant data, information and analysis to get the settings right.

It is possible to create a vibrant, sustainable and profitable green hydrogen industry to support decarbonization of Australian and global economies, but it won’t happen by accident. Careful planning is essential, and communities must be involved in deciding where water will come from and how it can be accessed.