What started as a simple errand to deposit a check at a bank drive-through became the kind of “aha” moment found mostly in books and movies.

Georgia Tech researchers had been working on an idea to simplify traditional direct air capture (DAC) systems. Their approach used ambient wind flow to draw air across a new kind of coated carbon fiber to grab CO2. That would eliminate the loud fans used in many systems. And the carbon fiber strands could be quickly heated to release the captured carbon dioxide with minimal heat loss, boosting efficiency.

But they were struggling with how to deploy these new sorbent-coated carbon fibers for maximum effect.

“I had to go deposit a check at the bank, and I went through the drive-through. They had the old pneumatic tubes that come down to transport documents,” said Ryan Lively, Thomas C. DeLoach Professor in Georgia Tech’s School of Chemical and Biomolecular Engineering (ChBE). “There are not many times you have a light bulb moment in your career, but I saw the tubes and I realized, we could put the fibers in something like a bank teller tube canister.

“That’s pretty much what we did, and it worked.”

With the pneumatic tube-inspired modules in place, the team began testing their system. They found they could produce carbon dioxide with sufficient purity for underground sequestration and eliminate many of the substantial upfront costs of building typical DAC systems. They described their design and approach in an article published June 12 in the journal Joule.

“This work not only conceptualized a new generation of DAC systems but also showed practical operations of our invention to some extent,” said Won Hee Lee, the paper’s first author and a former postdoctoral scholar in Lively’s lab. “We already successfully captured ambient CO2 with our lab-scale module. Now it’s important to scale up the module. Since all the components of our system are commercially available and fabrication is relatively easy, there should be few technical hurdles to making the module in large scale.”

At least in theory, the team has performed that scale-up, using their experimental data to project the economics of a practical system. They found the system could capture CO2 for $150 to $200 per ton—significantly less than commercial systems under construction that are estimated to capture carbon for $300 to $600 per ton.

A simpler approach

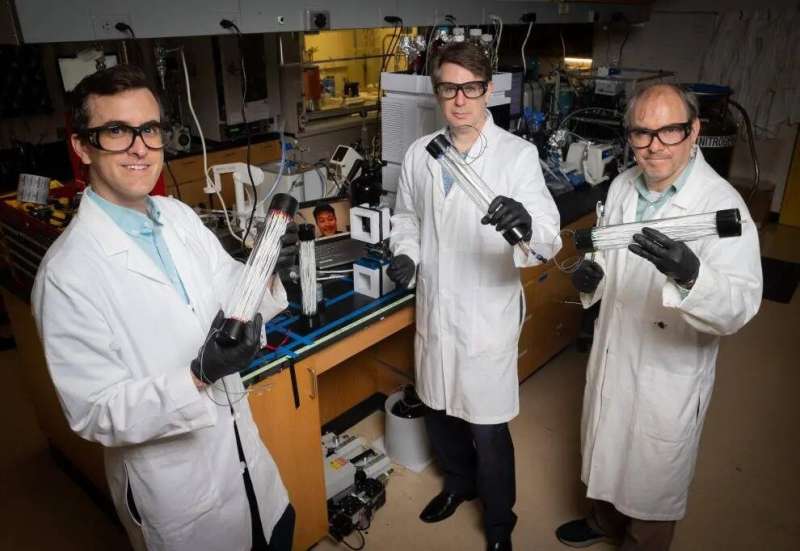

The study’s co-authors include researchers in ChBE who’ve positioned Georgia Tech as a leader in direct air capture technology. Professors Christopher Jones and Matthew Realff work with Lively on the full spectrum of DAC, from the molecular to the systems level.

This work presents two key advances. DAC systems use heat to release CO2 from saturated filter materials. The CO2 is collected and then can be pumped underground or perhaps used to make fuel or chemicals. Typically, systems use an external heating source. Steam is a popular choice, because it’s quick and powerful, but it’s also damaging and requires an extra condensing step. These systems also require insulation to prevent all that heat from escaping, so they’re bulky and expensive.

Lively and the team created unique carbon fiber strands coated with a carbon-loving sorbent. The carbon fiber core heats from the inside out, resulting in fast and even heat distribution.

“The fibers are very, very uniform. When you hook all this up to an electrical system, you distribute that energy remarkably homogeneously, which is unusual for a resistance heating system,” Lively said. “We’re not the first to think of resistance heating to regenerate a carbon capture device. But typically, the heating was either slow or not uniform. There are places where you’re heating up the air instead of the thing you’re trying to heat.”

The researchers’ system uses fewer components overall. The design deploys a series of their bank-tube-inspired modules with carbon fiber strands in a circle to capture CO2 no matter which way the wind blows. The system uses a single vacuum pump that spins from module to module during the regeneration phase. And there’s no need for steam generators, pumps, and condensers to release the CO2 and “recharge” the strands. Both of those changes mean the system is simpler overall and cheaper up front to build and deploy.

“The capital cost of this system is significantly lower than many of the current DAC systems based on the lack of auxiliary systems like steam generation,” Realff said. “The energy cost is still a challenge, and we need to increase the amount of CO2 we can adsorb in the device so that the sensible heating of the fibers does not consume too large a portion of the overall heat.”

But Realff said the rapid heating and fast cycling of the system holds great promise for a more productive approach to direct air capture. “The fact that we could produce a working prototype and demonstrate it at bench scale in months is a remarkable feature of the technology,” he said.

Ideally, the team’s DAC system could be situated with a wind farm, using renewable energy from wind turbines. But even using power from the current grid, Reallf’s analysis showed the team’s design would still remove enough CO2 from the atmosphere to be carbon negative.

Another advantage to the team’s approach is the carbon fiber strand. The material has the right mechanical and electrical properties, and it’s readily available, sustainably manufactured in large quantities, and not prohibitively expensive.

Now the team is looking to boost the quality of the carbon dioxide they can produce. They’ve achieved 80% purity—good enough for underground storage, but they’d like to reach the 99% purity needed for productive reuses like making chemicals or fuels. They’re working with the Georgia Tech Research Institute to refine and automate their system with that goal in mind, and they’re working toward installing a test system atop a campus building.

“I have worked on DAC for over a decade, and almost all designs I have seen rely primarily on heat energy for desorption,” said Jones, who also is ChBE’s John F. Brock III School Chair. “A technology that allows for both rapid, local heating and use of renewable electricity expands the DAC technology developer’s array of design options.”